Below is a list of articles which feature Cadfil software, or have been written in part by the Cadfil team.

Jet engine nozzle project - JEC Magazine 2022

Vessel design and analysis - Cadfil and Predictive Engineering 2022

Large filament wound buoys - Composites World 2021

Offshore wave energy - Leeuwarder Courant 2020

Developments in filament winding software - JEC Magazine 2019

Discussion of new AFP winding feature in Cadfil (December 2023)

There is currently great interest in the design and manufacture of Composite pressure vessels (COPVs), particularly for applications in the areas of energy storage and sustainable transportation using hydrogen. The only viable manufacturing process for such vessels is via the use of the filament winding process. This article discusses how in some circumstances the efficiency of COPVs can be improved by using a hybrid process of filament winding and localised reinforcement using an Automatic Fibre Placement (AFP) methods. Reference is made to the Cadfil software system which can be used for the design and manufacture of components using both manufacturing technologies using newly introduced features.

Cadfil/C2ES jet engine nozzle project (June 2022)

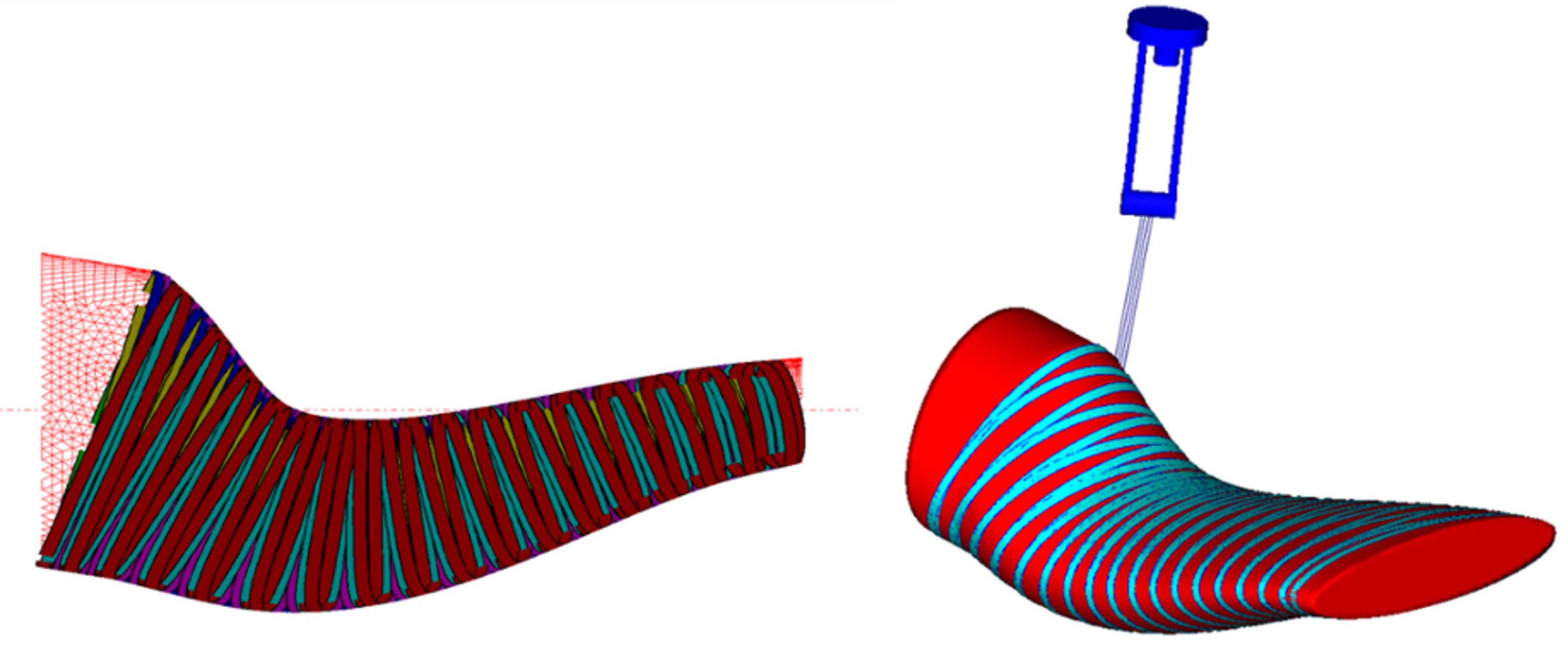

Cadfil Software has been published in JEC magazine for our recent work with both C2ES and KCarbon in Korea. Read the full article Filament winding process based on jet engine nozzle geometry for stealth aircraft at JEC Composites

In the case of an S-shaped double serpentine nozzle such as this, it is essential to create an accurate fibre placement and winding trajectory through manufacturing (CAD/CAM)design tools in advance. However with this non-axisymmetric shape this is more difficult.

Because this component is primarily a complex duct (a multi-curved tube of a variable section) a method based on using helical paths generated relative to a curved spine was used. This is analogous to winding a helix relative to the axis of a normal round pipe whose axis is a straight line.

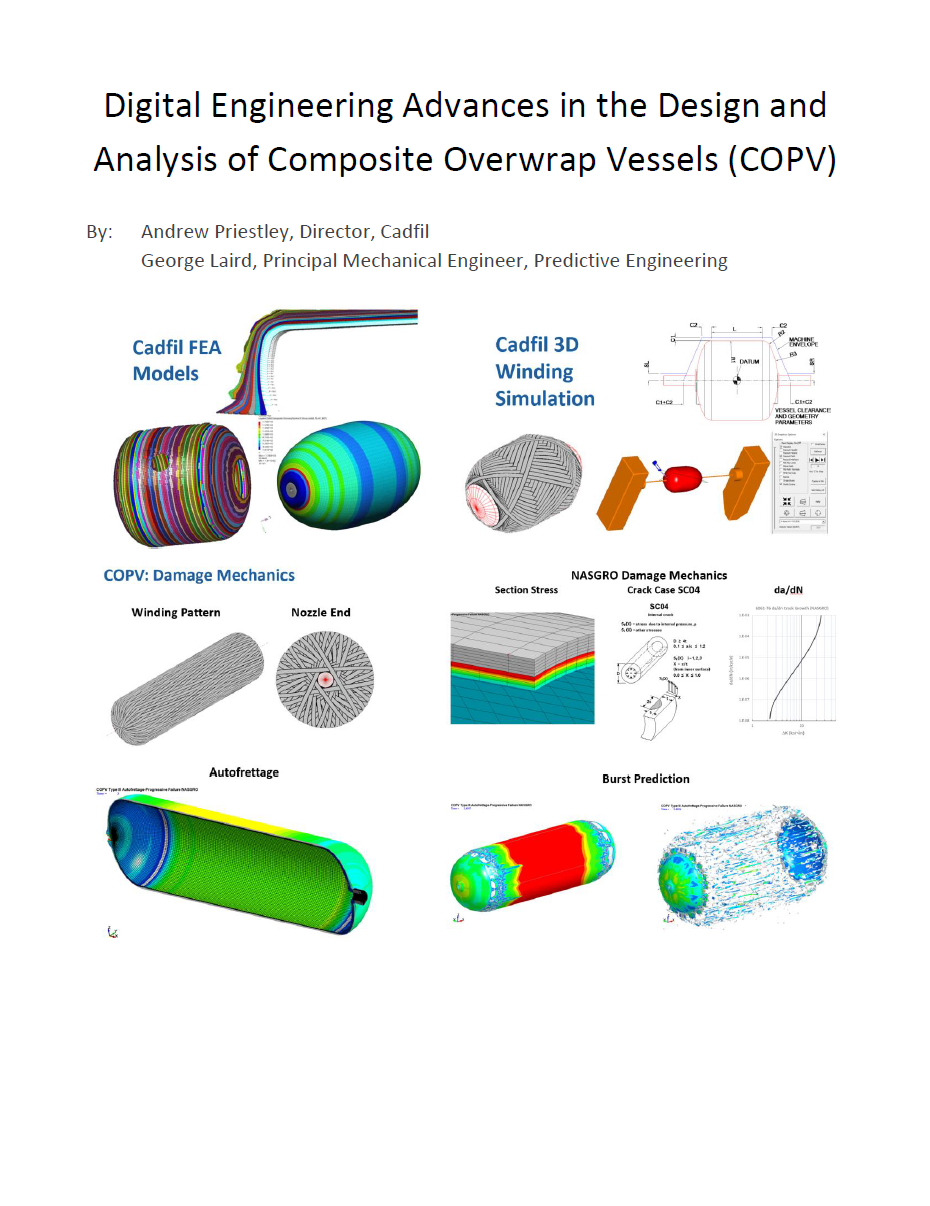

Cadfil article on Advances in the Design and Analysis of Composite Overwrap Vessels (June 2022)

Cadfil director Andrew Priestley has written an article in collaboration with George Laird of Predictive Engineering. This article discusses the current interest in development of high-performance COPVs, and how modern techniques and software can be used to design these vessels more efficiently. To read the entire article, please click the picture below

Composites World Magazine article on large filament wound buoys (September 2021)

A novel wave energy system using large filament wound buoys is featured in an article in Composites World magazine. The article concerns our work with CorPower Ocean, as discussed in February, and their work in offshore wave energy. In this project we also worked closely with Autonational BV who developed the winding machine used in the project. Cadfil software was used to create the winding patterns, and to create the laminate structures for FEA analysis during development of the product. The loading of the buoy is complex and minimising weight is key to achieving efficient energy harvesting so the use of Cadfil was very important for the efficient design of the winding.

Leeuwarder Courant article on Cadfil Filament Winding in offshore wave energy (September 2020)

Filament winding has many diverse applications, in a recent project Cadfil was used extensively in the part production and FEA analysis of new offshore wave energy technology being developed by CorPower Ocean, from Sweden. These large buoys at about 9m in diameter are made of a wound glass-fibre composite which has to withstand extreme conditions at sea and substantial operating stresses. The large winding machine for the project has been developed by Autonational BV from the Netherlands. By creating a composite product instead of steel, it makes the buoy more lightweight and corrosion resistant, both being critical criteria for a successful and efficient product. More information can be found in the press article from the Leeuwarder Courant an online newspaper.

Cadfil feature in JEC composites magazine (October 2019)

Cadfil director Andrew Priestley has written an article in the latest edition of the JEC composites magazine, This article discusses developments in filament winding software over the last 30 years, and discusses some of the most recent new features which are required for some modern manufacturing processes, including developments in machine simulation, developments in pipe fitting winding and integration of the winding process into the design system. To read the entire article, please click the picture below